The Challenge

A 10,000 SF office in Lancaster, PA is a bright and vibrant workplace. However, the abundance of direct sunlight and busy workstations places a high demand for cooling on hot afternoons. Spikes in cooling demand during peak hours cause the building to operate inefficiently. Intense cooling also contributes to higher demand charges from the utility. The challenge was to reduce peak cooling loads with an easy-retrofit solution without compromising the bright atmosphere or comfort of the space.

The Solution

The solution was to install CALLA TEMPLOK Energy Saving Ceiling tiles to help manage the heat load during peak hours. As the building warms, the Phase Change Material (PCM) in the ceiling tiles absorbs heat in the melting process, offsetting the need for mechanical cooling. The Templok installation effectively converted the ceiling into a “thermal battery” controlled by the building’s setpoints. The PCM was frozen efficiently in the morning using cool outdoor air. Setpoints were staggered throughout the day to melt the PCM and save cooling energy.

Phase Change Material (PCM)

Finding Energy Savings Solutions

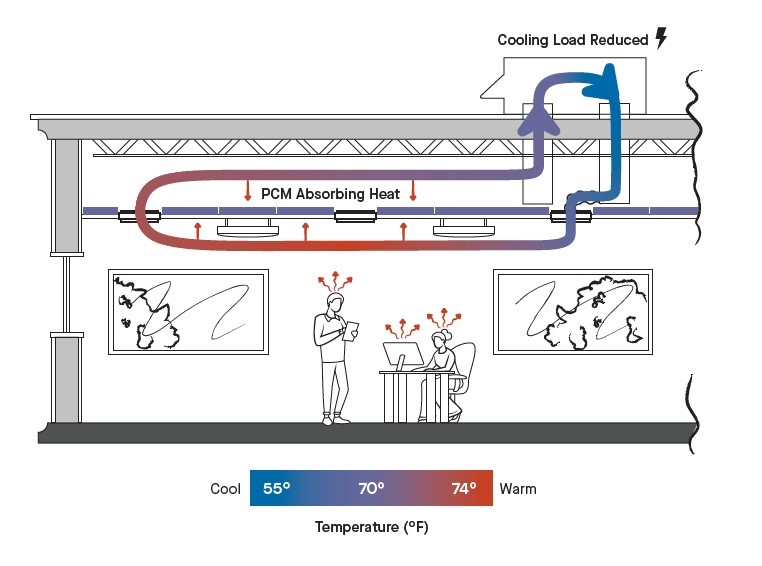

(Fig 1) The PCM absorbs heat from the air, lowering its temperature and reducing the cooling load.

Installation: CALLA TEMPLOK ceiling tiles were installed into all full grid openings, covering approximately 55% of the acoustical ceiling area and 25% of the 10,000 SF zone served by the air handling unit.

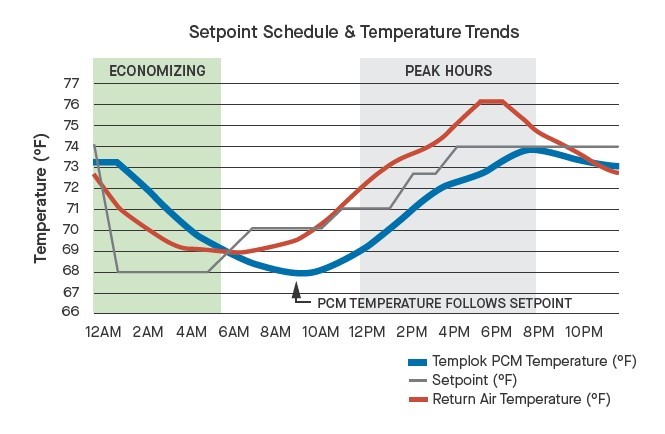

Control Strategy: The Building Management System (BMS) was programmed to leverage PCM thermal mass. In the early morning, the thermostat was set to 68°F with economizing enabled. Throughout the day, the setpoints were gradually increased to 74°F, maintaining thermal comfort while allowing the PCM to melt

Monitoring: Sensors were placed on the Templok tiles to monitor the PCM freezing and melting behavior. Each hour, the amount of heat absorbed by the tiles is roughly equal to the amount of mechanical cooling load reduced (Fig 1).

Pre-Cooling: The BMS was programmed to economize and pre-cool the building overnight. Economizing provides efficient cooling by flushing the building with outdoor air when the temperature and humidity are low. The PCM in the ceiling occupies a large surface area that was readily “charged” (i.e., frozen) overnight by air circulating through the room and plenum.

Leveraging the PCM: The thermostat was set to 68°F from 12:30 AM through 6:00 AM and gradually increased to 74°F by 4:00 PM to drive freezing and melting in a pattern to reduce cooling demand during peak hours. The PCM’s temperature followed the setpoint schedule with a few hours lag. Understanding its response helped the operator controllably “charge” and “discharge” the PCM through simple setpoint adjustments.

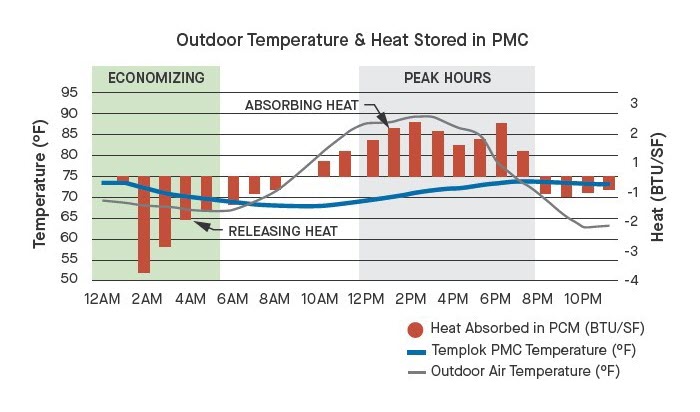

Load Shifting: PCM temperature data was used to estimate energy transfer using the material’s known thermal properties. Figures 2 and 3 illustrate the PCM’s temperature pattern and the estimated hourly cooling load offset by heat stored in the PCM.

(Fig 2) Temperature trends on September 19th, two days after Templok installation and setpoint changes.

(Fig 3) Temperature trends on September 19th, two days after Templok installation and setpoint changes. Outdoor conditions and Templok heat storage on September 19th.

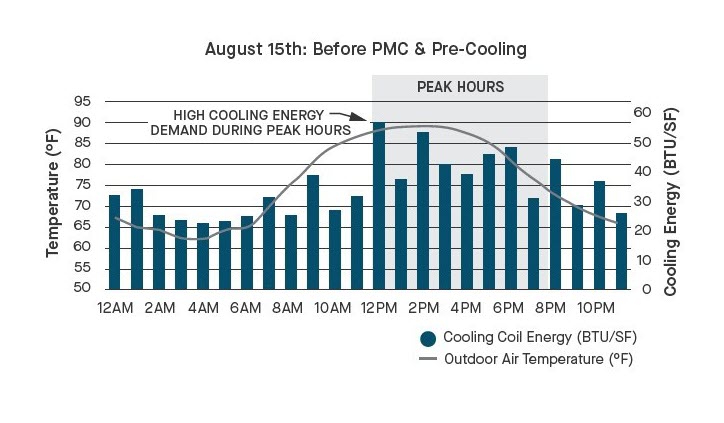

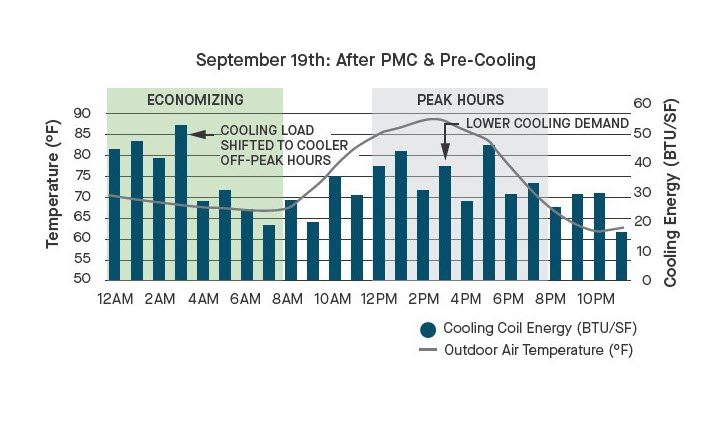

Peak Load Reduction: In Figures 4 and 5, cooling energy was compared on weekdays with similar outdoor temperature patterns before and after the PCM retrofit and pre-cooling. Before, peak cooling demand occurred in the hot afternoon hours. After the retrofit, afternoon demand was significantly lower. The peak was shifted to the early morning when cooling was more efficient.

Comparing these days, pre-cooling the building’s thermal mass – enhanced by the PCM – reduced the afternoon peak demand by about 30%

(Fig 4) Cooling energy before PCM

(Fig 5) Cooling energy after PCM and pre-cooling